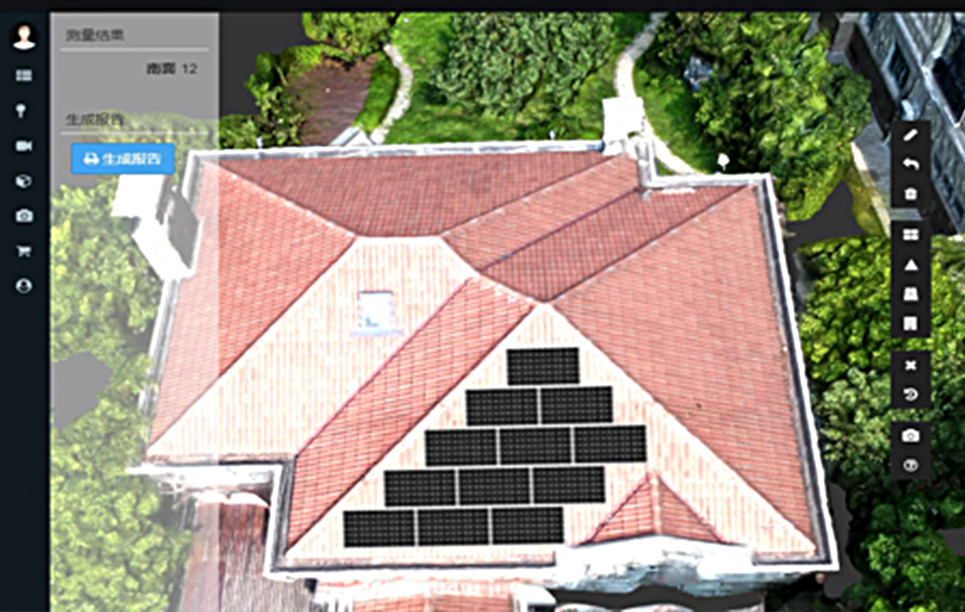

Traditionally, the original blueprint of buildings was used as a reference of measurement when carrying out planning and calculations for installing new photovoltaic stations. An alternative is for workers to manually scale the roofs and take measurements by hand. The process is long, tedious and pose a safety hazard to workers. These processes are often affected by inclement weather and equipment constraints. Ultimately, it reduces the accuracy of measurement data and efficiency of photovoltaic station installation.

Using our drone integrated visible light camera along with our backend 3D modelling software, it is possible to build a 3D model of a roof in a short amount of time. This model is precise down to the centimeter scale and exports out easily as a CAD drawing, making it convenient for future engineering design works as well. This method can easily replace the highly complex traditional method of photovoltaic station design planning, while being safer and more efficient.

High precision 3D map of the mines are stored in the cloud, with clear visualizations for management;

High precision 3D map of the mines are stored in the cloud, with clear visualizations for management;

Intelligent nondestructive modification, can be repeated disassembled;

Intelligent nondestructive modification, can be repeated disassembled;

High robust, safety and efficiency;

High robust, safety and efficiency;

It can continuously optimize the operation based on big data;

It can continuously optimize the operation based on big data;

Nearly 60000 km without accident

Nearly 60000 km without accident

Slight occlusions, burns and cracks cause solar panels to generate hotspots, affecting the electricity generation efficiency of the solar panels. These damages could lead to permanent damage of solar-powered battery cell components or even trigger a fire hazard. Traditional maintenance methods rely on human patrols, but given that photovoltaic stations usually span over large areas with great changes in altitude throughout the stations, this method is inefficient and can pose safety hazards. In addition, inspection results are based on the staff's experience in detecting damages, which commonly result in deviations of the reliability of inspection results.

Slight occlusions, burns and cracks cause solar panels to generate hotspots, affecting the electricity generation efficiency of the solar panels. These damages could lead to permanent damage of solar-powered battery cell components or even trigger a fire hazard. Traditional maintenance methods rely on human patrols, but given that photovoltaic stations usually span over large areas with great changes in altitude throughout the stations, this method is inefficient and can pose safety hazards. In addition, inspection results are based on the staff's experience in detecting damages, which commonly result in deviations of the reliability of inspection results.

High precision 3D map of the mines are stored in the cloud, with clear visualizations for management;

High precision 3D map of the mines are stored in the cloud, with clear visualizations for management;

Intelligent nondestructive modification, can be repeated disassembled;

Intelligent nondestructive modification, can be repeated disassembled;

High robust, safety and efficiency;

High robust, safety and efficiency;

It can continuously optimize the operation based on big data;

It can continuously optimize the operation based on big data;

Nearly 60000 km without accident

Nearly 60000 km without accident

微信公众号

Shanghai Headquarters Address: 6F, Block B, Building 1, No. 800, Zhangjiang Naxian Road, Pudong New Area, Shanghai

Tel: 021-58212107 Post Code: 200124

Address of Hangzhou Branch: Building 9, No. 1818-2, Wenyi West Road, Yuhang Street, Yuhang District, Hangzhou

Contact number: 0571-87562630 Zip code: 311121

Email: sale@boonray.com

Copyright©2018 Shanghai Boonray Intelligent Technology Co., Ltd. All rights reserved

Terms of use Legal Notices